Will cucumbers soon cost us five euros a piece? Hopefully, things won't get that bad. But many consumers can’t believe their eyes as prices for food and other consumer goods go up a few cents every week. In the worst case, this can lead to hardship for low-income families. But why are the prices rising? We'll try to explain by looking at logistics processes. It is important to understand that logistics contributes only a small part to inflation and is not its root cause. The interrelationships are complex, and we’ll do our best to break them down.

- Causes of inflation

- Logistics: Narrow margins, little room to adjust

- Where do logistics companies notice the price increase?

- Price spiral reaches retail

- What brands can do now

Causes of inflation

Inflation has been a concern for consumers and companies since last year. The countries in the European Union have an average inflation rate of 7,8 percent . But what is behind this? Inflation can have many causes. In most cases, it is a complex web of events in global policy and trade. In the current case, two main factors are coming together: the foothills of the Corona pandemic and the current energy crisis resulting from the war in Ukraine.

The pandemic had a massive impact on the labour market, on certain sectors of the economy (partly positive, partly negative) and on global supply chains. In many industries, workers had to be laid off during the pandemic and are now partly missing. Some industries boomed, which increased demand in the long term. Historically, as demand increases, so do prices. Demand also had an impact on supply chains. In shipping, there were sometimes massive problems with container shortages. The demand caused logisticians to transport large quantities of goods from producing countries in Southeast Asia to Europe and the U.S., This eventually caused empty containers to pile up on one side of the globe while they were missing elsewhere. Although the hot phase of the pandemic is over, these developments are still continuing to some extent.

The political tensions between Russia and the EU and its allies that started late last year are having a massive impact on energy security here at home. The war in Ukraine, which began in February, has exacerbated this situation. Energy costs are rising. Also because many gas reserves in the EU have been depleted after a cold winter. At the same time, the oil market reacted, leading to high prices at the pumps. This complex web affects all industries, including retail and the logistics behind it. What reaches the end customer is called inflation.

Logistics: Narrow margins, little room to adjust

Traditional logistics has always operated with quite narrow margins. This applies above all to traditional transport services, but also to some extent to warehouse logistics. This works well as long as the market remains stable and seasonal fluctuations predictable. It becomes more complicated precisely when the running costs for logistics providers change. Tight margins mean that service providers have little leeway to absorb rising prices. They have to pass these on to retailers relatively quickly. So after a while, these price increases also reach the end customer. That is inflation.

Where do logistics companies notice the price increase?

Where are logistics professionals already noticing inflation? Prices are going up in pretty much every aspect of logistics. Take shipping, for example. A container ship consumes thousands of tons of heavy oil per year. On top of this, shipping companies pay ports high fees to be allowed to dock and unload. Shipping companies also employ many thousands of people. Now, prices for each of these cost factors have risen over the past year. Fuel is more expensive, ports have increased fees due to increased demand from the pandemic, and simultaneous staff shortages and personnel costs for qualified staff have been rising for years.

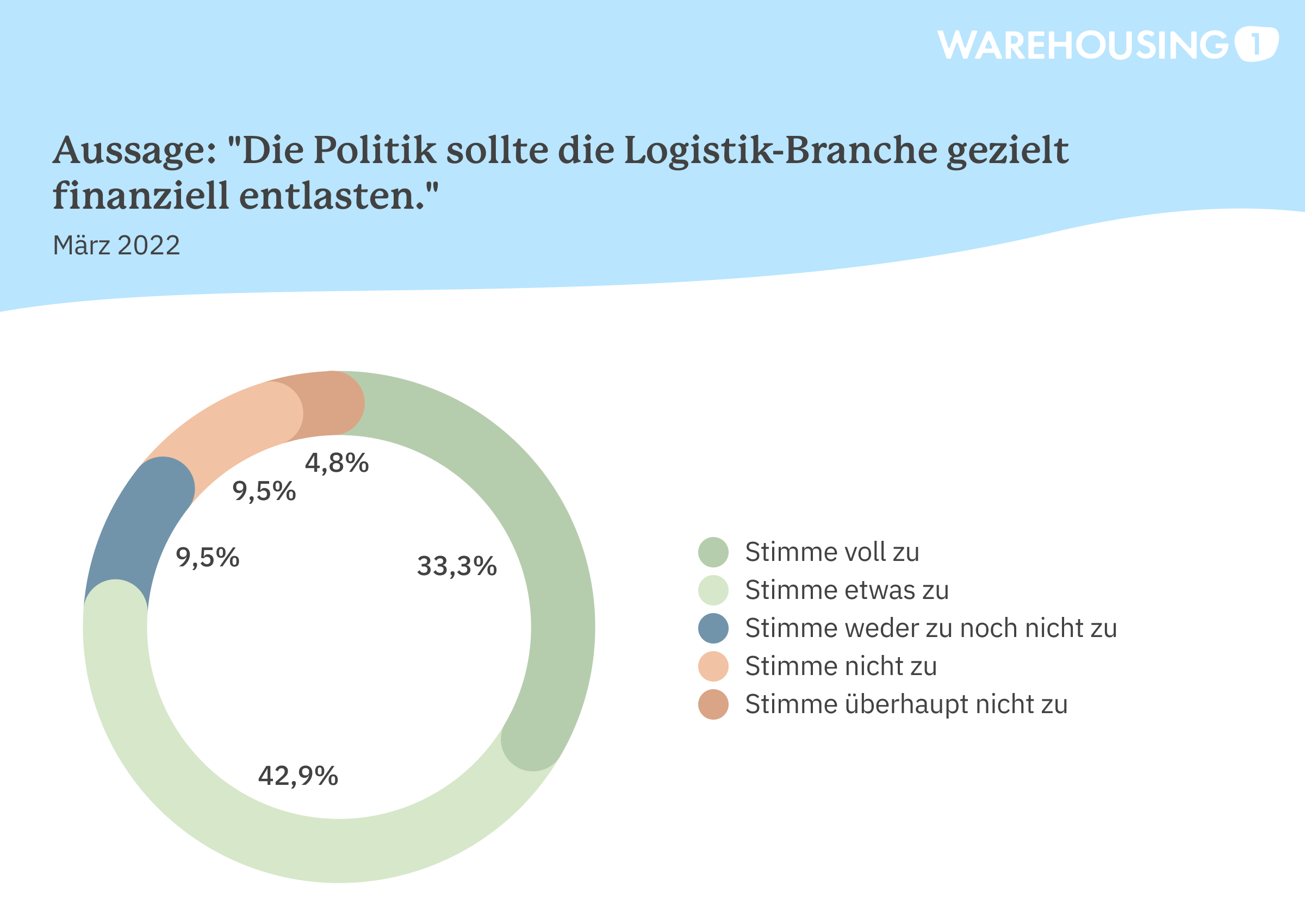

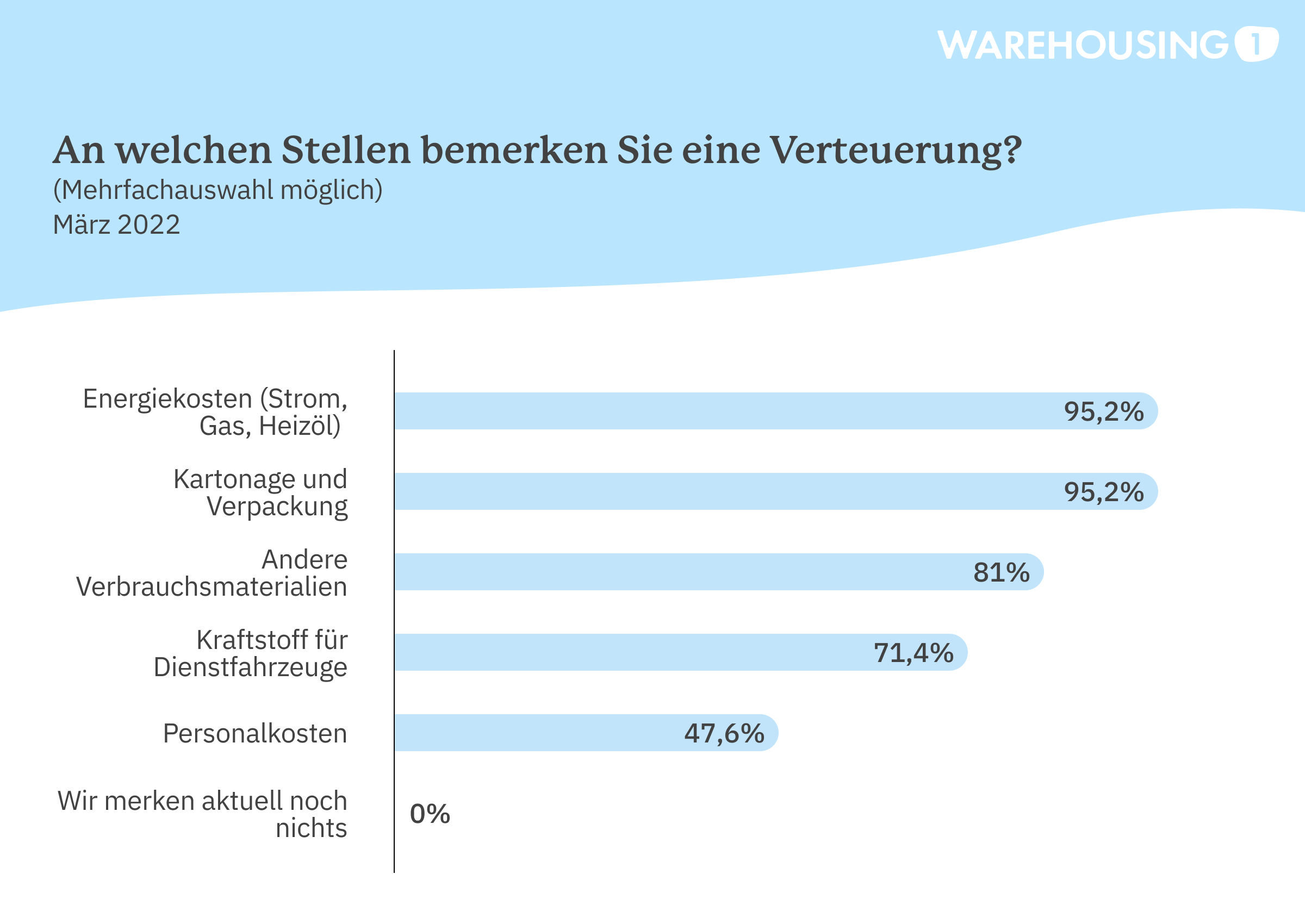

The situation is similar in warehouse logistics. Warehousing1 recently conducted its own survey among warehouse logistics experts. 100 percent of those surveyed said they were already noticing the higher costs in their day-to-day business. But in which areas do they notice inflation? Almost all respondents noticed price increases in cardboard packaging, packaging materials and energy costs.

Energy costs

Logistics companies consume energy in many places. To heat or coolwarehouses, to power computers and offices, or to run electric forklifts or conveyors. Ninety-five percent of our respondents said they are already noticing rising energy costs. No wonder, because in March 2022, Germans had to spend 39.5 percent more on energy than in the same month last year.

Fuel

The fact that fuel prices influence logistics is no surprise. Trucks and delivery vehicles that bring everyday goods to us and to the shelves largely still run on gasoline and diesel. But the aforementioned ships or transport aircraft also pump gas. The warehouse logistics operators in our survey are also affected by fuel prices. 71.4 percent said they noticed the increase in fuel prices for their company vehicles.

Cardboard and packing

Cardboard packaging is an essential part of logistics processes that keep the retail industry running. Every good, whether it is delivered directly to the end consumer or to a supermarket, is packaged in some way. Usually with cardboard. One warehouse operator we interviewed anonymously told us that the price of basic shipping cartons has nearly tripled since last year.

Personnel costs

Inflation naturally also affects personnel costs. This affects new hires in particular. Potential employees who apply for a job keep a close eye on inflation. In order to maintain their standard of living, they will ask for more money in their new job. This is not just the case in logistics, but affects all industries. Higher wages will soon have an impact on the price.

Transport costs

Every good has to be moved. To the warehouse, to the end customer or to the stationary retail trade. The costs for these transports are rising sharply. On the one hand, this is due to demand; for example, from shipping companies, who have themselves handsomely compensated for the highly coveted spaces on their vessels. But it is also due to running costs, which are rising in every area of logistics.

Price spiral reaches retail

Inflation happens with a slight delay. This is because it always takes a little time for price increases to reach the end customer. After all, companies can't change prices every time it fluctuates; that would only confuse clients and consumers. But when it becomes apparent that an upward trend in prices is taking hold, service providers have to act sooner or later. Otherwise, rising running costs can significantly hurt a company. In the case of the warehouse logistics providers we surveyed, only 23.8 percent had already passed on prices to their customers at the end of March. However, 61.9 percent were already planning to raise prices.

The impact on logistics is not limited to direct costs. Another logistics expert explains what the near future could hold: "The real difficulties will be delayed when people buy less because they need the money elsewhere."

Fabian Sedlmayr, Founder and Managing Director of Warehousing1, comments: "Inflation undoubtedly affects the entire logistics industry, but it also has an impact on society as a whole. After all, these costs reach the end consumer at some point. It is concerning when purchasing power as a whole declines. The warehousing and fulfillment industry is very closely linked to brick-and-mortar retail and the e-commerce industry and would be heavily affected by a decline in retail sales."

What brands can do now

The pandemic already showed how important it is for retailers to be able to respond to unforeseeable events with their logistics. This remains relevant in the face of rising prices. External logistics setups often offer retailers significant economies of scale and can better cushion rising operating costs. In the event of a sharp drop in demand – if there is a recession, for example – they can also save costs with a logistics provider that offers an "on-demand" pricing model . Warehousing1 will be happy to help you set up your fulfillment correctly, making it more crisis-proof.