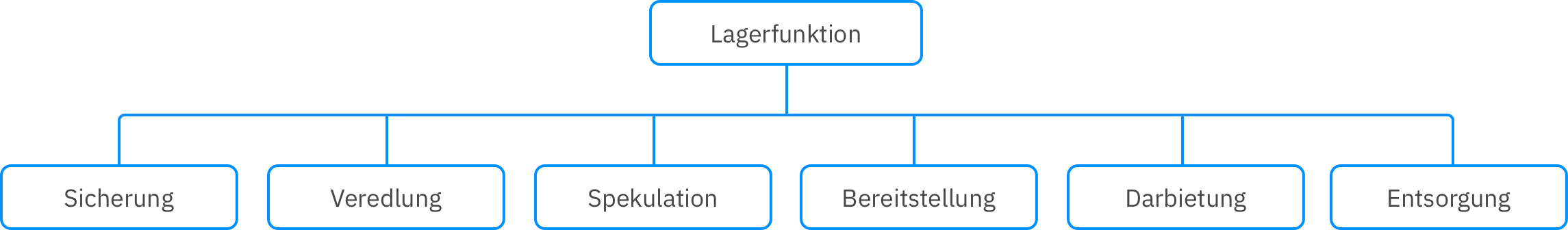

Just as the products in the pantry, kitchen, storage room or bathroom were purchased with different intentions, the goods that are in a warehouse and the associated warehouse also have different functions. So, it is not only categorized into different types of storage but also distinguished between different storage functions. In the following we would like to explain exactly these subdivisions.

Very similar functions are safeguarding and provisioning. Both ensure that goods can be in the right place at the right time - despite crises, fluctuations in demand or possible difficulties in the supply chain. In the speculation function, the prices of goods are expected to rise, while in the refinement function, the value of wine and cheese, for example, is increased during the storage period. The presentation function is familiar to consumers primarily from the retail trade, where goods are presented in salesrooms. The disposal function is also very important for the environment. Here, empties, waste and production residues are stored until they are properly disposed of or reused. Warehousing1 has the optimal warehouse for every purpose. Inquire directly now to receive offers perfectly tailored to your needs.

The function of the buffer storage is to smoothly compensate for disruptions and fluctuations in different production steps of the distribution chain. If problems arise in the first steps of production, the production process can be handled without further delays thanks to the reserves in the buffer stock. To optimize storage costs here, it is crucial not to have too much buffer stock and still be prepared for delay problems.

Similar to the pantry in every kitchen, the storage facility also fulfills the supply function, the buffer function and the speculation function. In the same way, seasonal goods are also stored to bridge the time when they are no longer available. In this case, the stock level decreases from time to time due to regular goods issues.

In the central warehouse, goods are not divided into storage areas at different locations, but are stored in bundles at one location. The top priority here is, of course, cost savings: the reduction of inventories, the bundling of goods, the minimization of transport routes and transport costs, and the opportunity to take advantage of volume discounts make the central warehouse attractive for numerous companies.

If the goods are not yet to be released for free circulation, they are delivered to a bonded warehouse at short notice. Here, duty unpaid items can be temporarily stored duty free. A distinction is made between public bonded warehouses, which are available to everyone, and private bonded warehouses, which must be set up for a very large storage requirement of a person.

Or do you need a new central warehouse? Warehousing1 supports you in your search for the perfect logistics partner. Simply inquire without obligation and receive individual offers.

The goods in a forwarding warehouse are usually just waiting to be delivered to the customer. Reasons for temporary storage are the time discrepancy between the arrival of the goods from the manufacturer and the receipt of payment from the debtor or the delivery time from two different suppliers. In addition to this, value-added services are also provided in the short-term warehouse by the associated forwarders.

Before the goods reach the sales market, they must be stored. Distribution warehouses, also known as delivery warehouses, are the central point for this. Here, for example, large supermarket chains can centrally store their packaged finished products, pick them and have them quickly delivered from the warehouse to nearby stores by trucking companies. But the delivery of goods to the end customer can also be organized here.

Smaller area, lower ceiling height, but very many and very high gates - the transshipment warehouse, unlike the previous types of warehouse, is not primarily used for storing goods. Here, goods are primarily sorted, divided into different consignments or combined from different consignments of local and long-distance transports. The volume of goods handled here is therefore comparatively high.

The picking warehouse is primarily used in shipping centers. Here, the goods must be easily accessible for the warehouse employees for picking, since the goods must be regularly removed and packed in partial quantities or individually. As soon as the number of goods runs out, new goods are procured from the manufacturer or from another warehouse and stored.

With a network of 1,000 locations, Warehousing1 has the right solution for every circumstance. Simply send us your inquiry now and receive a personal response within 24 hours.

Would you like to get started right away or do you still have questions about working with us? Click on one of the links below or simply fill out the adjacent contact form now. We will get back to you within the next few hours.

Email: [email protected]

Phone: +49 (0)30 629 3898 0

English

English